CONTINUOUS CENTRIFUGAL

BMA continuous centrifugal are used in almost sugar factories countries in the world. Thanks to that, when designing the new K 3300 it was possible to consider the experience gained in the daily use of the machines under the most diverse conditions of service, which resulted in an improvement of the main elements such as basket, pivot and housing.

Advantages and Characteristics:

- An optimum preparation of the massecuite for the separation process in the feeding device and the product distributor available in the center.

- Transmission by trapezoidal belt, with belt tension sensor as standard equipment.

- The vibration sensor and the electromagnetic flow meter are also standard devices.

Additional Elements:

- In order to achieve high processing capacities even with high viscosity masses, continuous BMA centrifuges (mainly for “C” or low grade massecuites) can be equipped with the new stepped TURBO 3 product distributor. This distributor increases the yield by 15 – 20% and considerably improves the purity of the sugars. The new turbo distributor consists of a stepped rotating cone surrounded by a bell that moves along with the distributor (it is no longer fixed, as in previous models). Through this bell, the distributor feeds on steam. The cooked mass flows down the inner surface of the cone downwards, mixing with the steam and heating up intensely and uniformly.

- The new model K-3300 has a basket of two stages: a first stage of pre-purging with 14° of inclination and a second, of intensive purging, with 30° of inclination. This double inclination is the reason for the large increase in capacity, compared to previous models. The first stage of 14° is a stainless steel screen and has a minimum duration of 5 harvests. The 30° part uses standard fabrics.

- Optionally, continuous centrifugal can be equipped with a dissolution device. Inside that device, located in the sugar space of the casing of the centrifuge, the separated sugar that comes out of the basket is dissolved with an appropriate agent to obtain a re-melt, which is evacuated from the centrifugal through two pipes.

Reference values:

| Characteristics | Unit | K 3300 |

| Upper basket diameter | mm | 1,300 |

| Screen area | cm2 | 19,500 |

| Housing height | mm | 1,030 |

| Gravity factor | g | 2,623 |

| Maximum speed | rpm | 2,000 |

| Massecuite “B”, cane | t/h | 24 to 35 |

| Massecuite “C”, cane (with Turbo 3) | t/h | 16 to 21 |

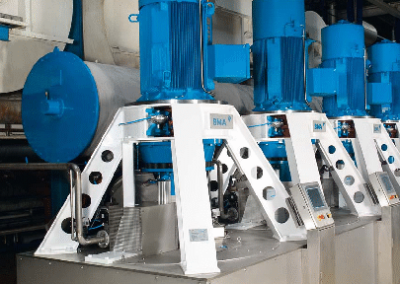

Image Gallery: